I check on the progress of The ETP 5885 Mini Notebook at the local commercial printer that makes them. This production run will be the last on Amazon Marketplace.

Happy Thursday! Today’s 30-Day Building ChallengeI am sharing “tangible things I do” related to my design business reboot for 30 days (5 days a week) to see if this is sustainable. See the October 10 GHDR Report for the details. sharepiece is a tour of Papergraphics, the commercial printer that makes my printed stationery projects possible. They’re five miles away from me in New Hampshire, and have been incredibly helpful in helping me start printing quality stuff for the past 15 years. They are the best, and I’m incredibly grateful that they indulge my fussiness and helping me cost things so I can sell locally-produced high-quality notebooks instead of going overseas. As I love paper and printing, it’s really a treat to have such a facility so close by.

While the notebooks themselves are still in production, I was able to grab some photos and talk to Frank, the VP who has been handling my account since 2009 despite him being super busy. He gave me a mini tour so I could reacquaint myself with the facilities, as it’s been quite a while since I’ve checked out the machinery.

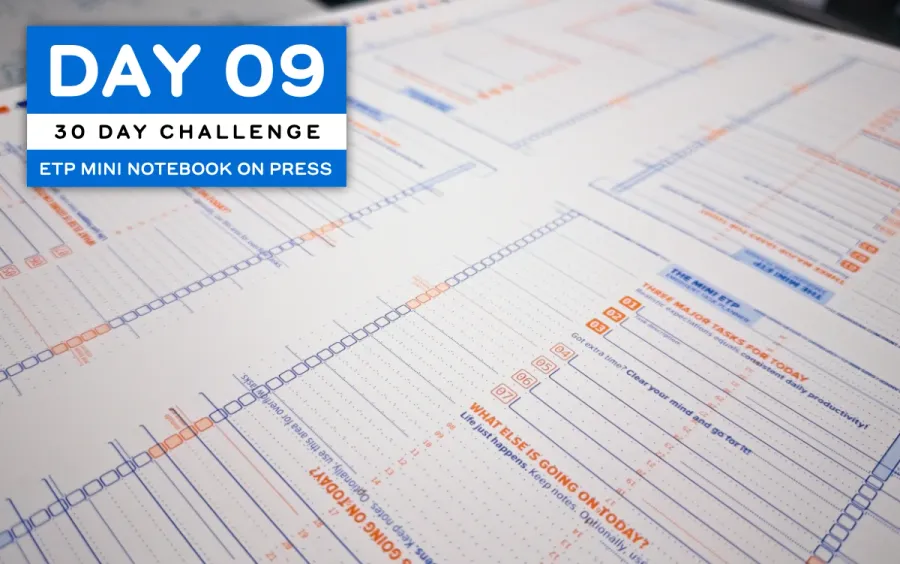

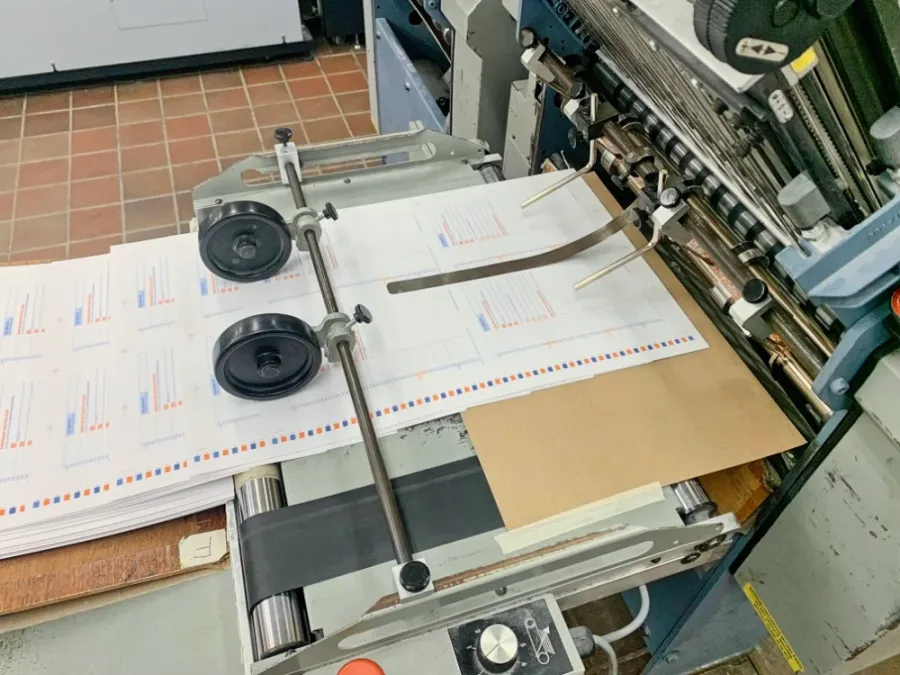

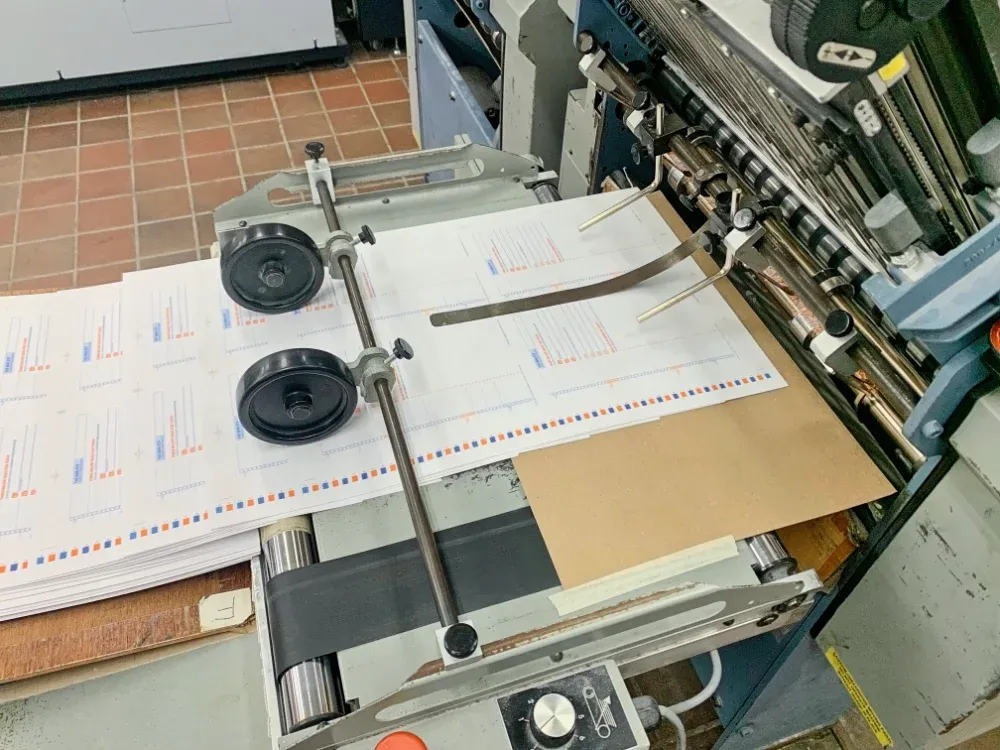

Internal Pages on the Heidelberg

The main body of the notebook is printed on nice heavy fountain pen-friendly paper using vibrant Pantone solid color inks on two lithographic plates on the Heidelberg offset press. This is different than a lot of other notebooks out there which use CMYK process color. The difference is subtle to most people, but I like it because designing for two plates of Pantone®-calibrated ink color which makes lines super-sharp and intense.

ASIDE: In this run of the notebook, I didn’t update the contact information on the inner pages, so they say davidseah.com instead of dsriseah.com. Frank told me that he almost had a heart attack when the press production staff told him about the discrepancyThis attention to detail is why I respect press people so much ❤️, and I assured him that it was fine because I anticipated this was the last run of this design, and I was counting on the insert to help with the transition. Sorry, Frank!

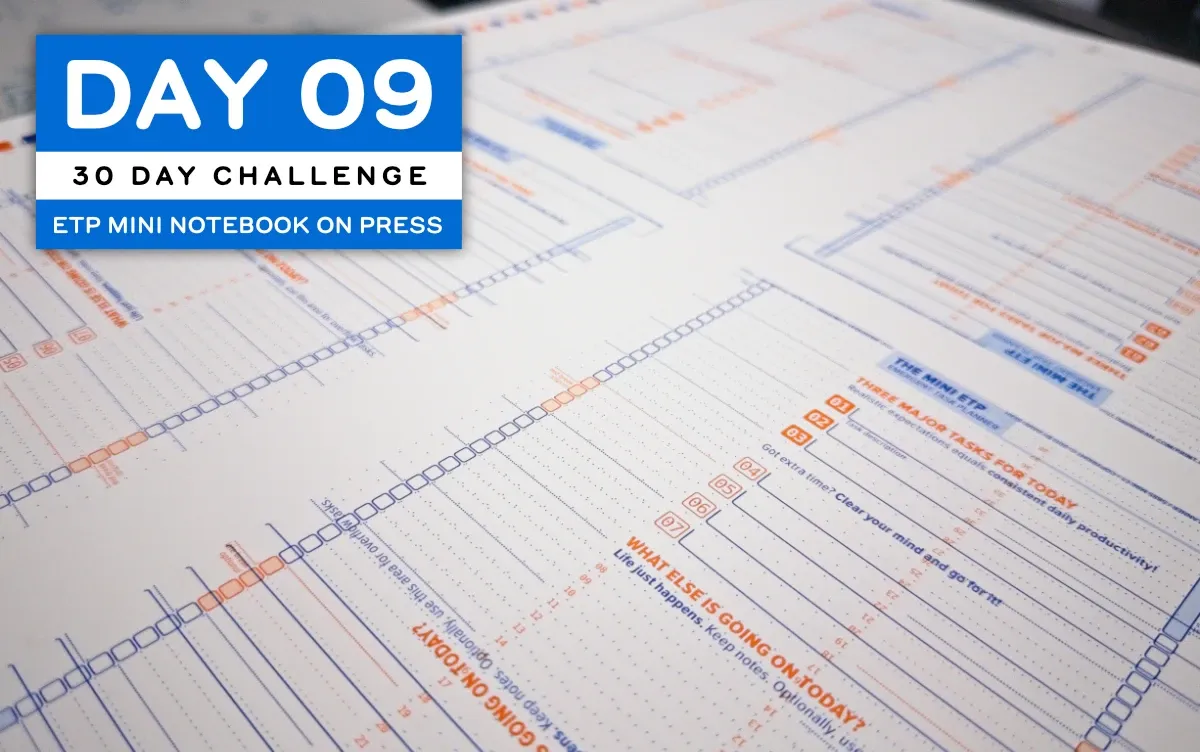

Here’s what the Heidelberg looks like! This is the highest quality press option available here, using photolithography up to (I think) 5 plates. However, there is a fixed cost to creating the plates and setting up the run that makes it cost effective when printing a lot of pages.

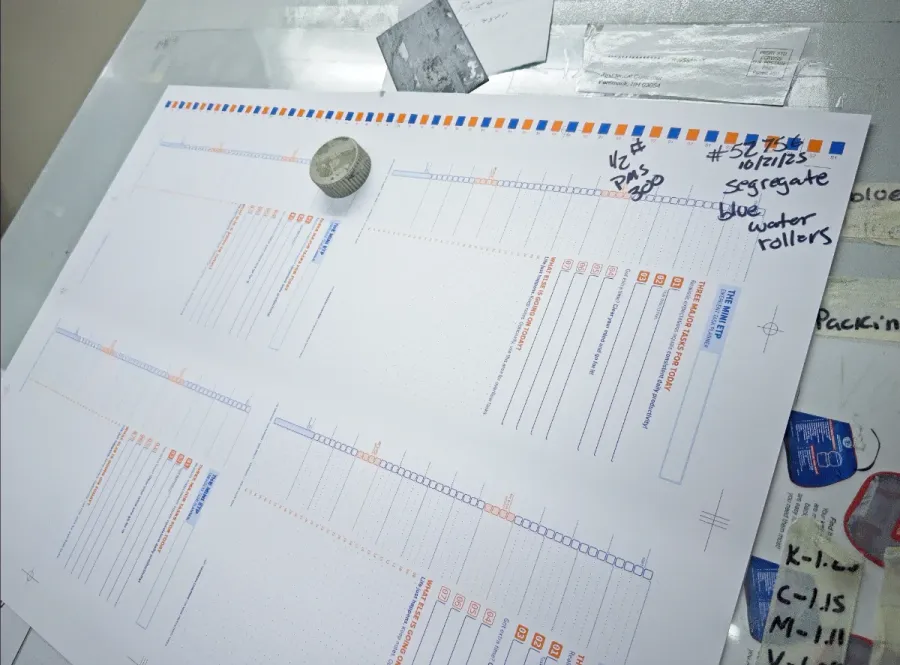

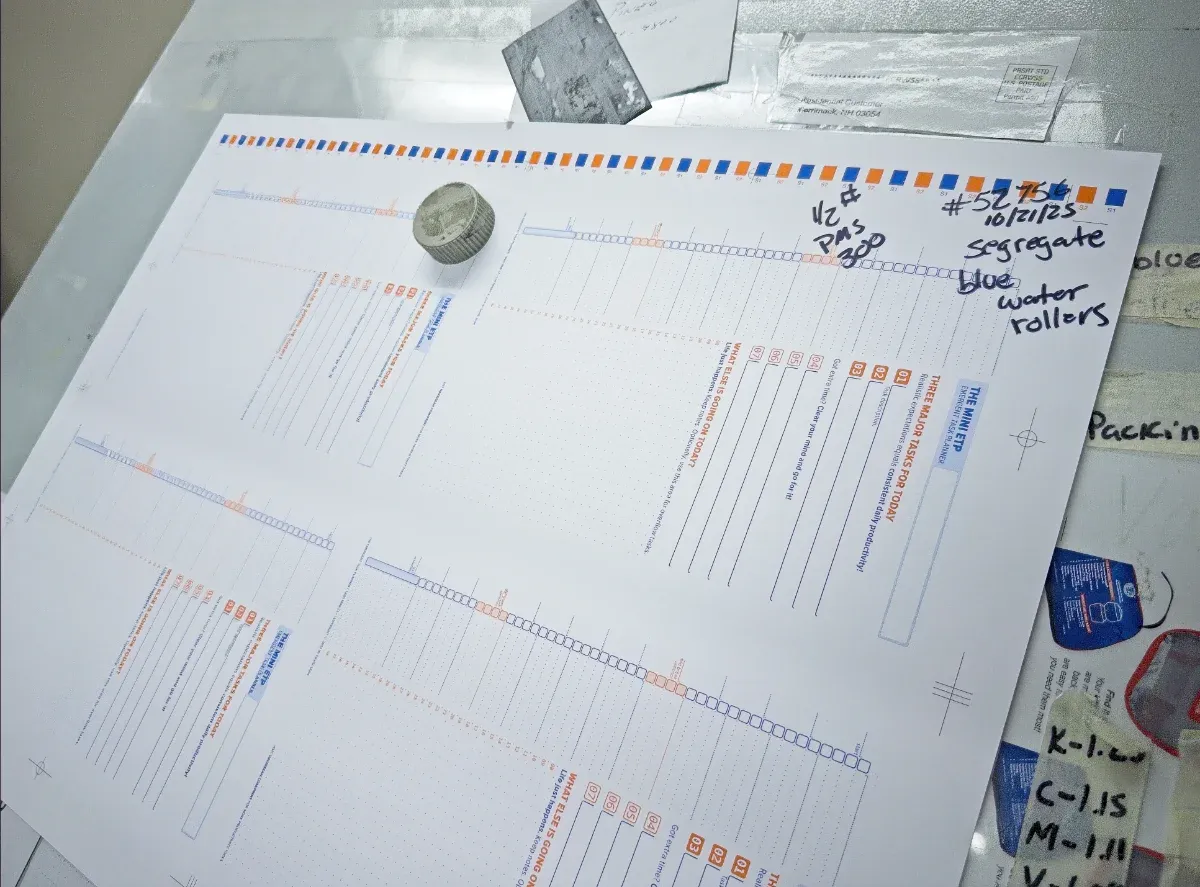

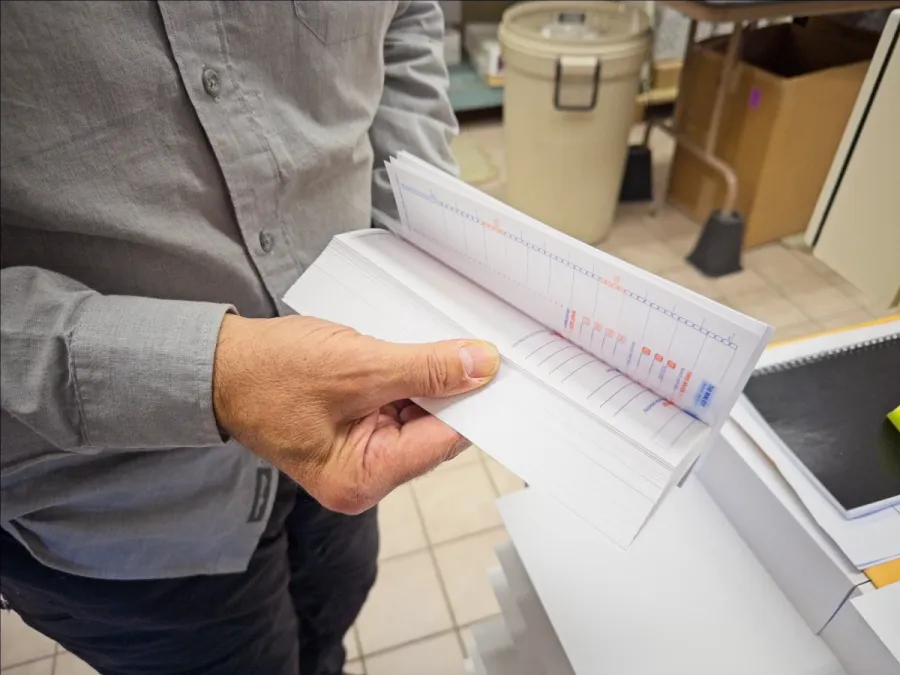

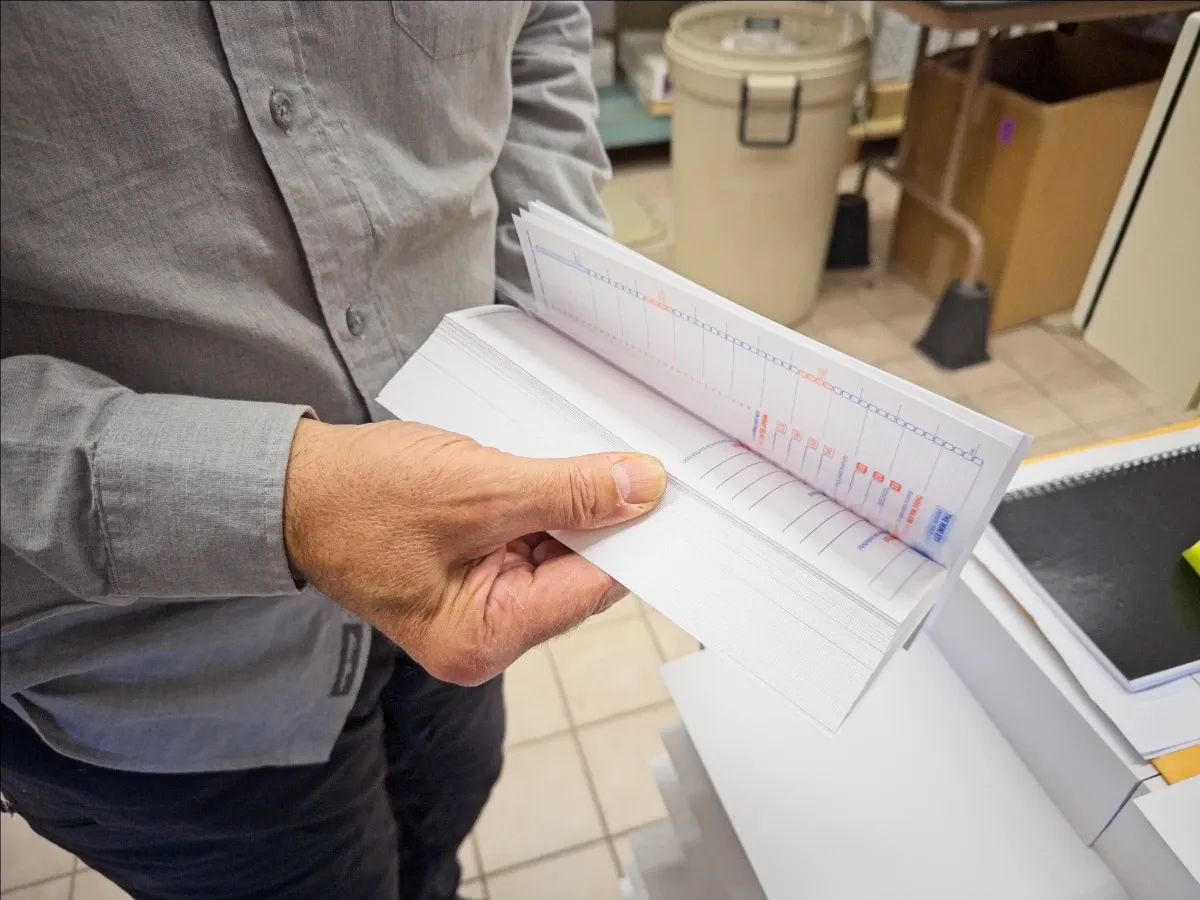

Frank explained that this stack of sheets is used to calibrate the plates. You can see the bottom of the stack is misaligned, and the adjustments converge to sharp alignment. An offset press like this uses one plate for each color used. My design uses two plates, but most other output uses 4 plates at minimum. Since each plate prints onto the piece of paper, you have to align them carefully so they print clean.

In the image above, you can see that the bottom test prints are not aligned at all. The registration improves as the press is adjusted by the operator.

After everything is set up, pages shoot out of the printer, 4 pages per sheet!

Front Insert Page

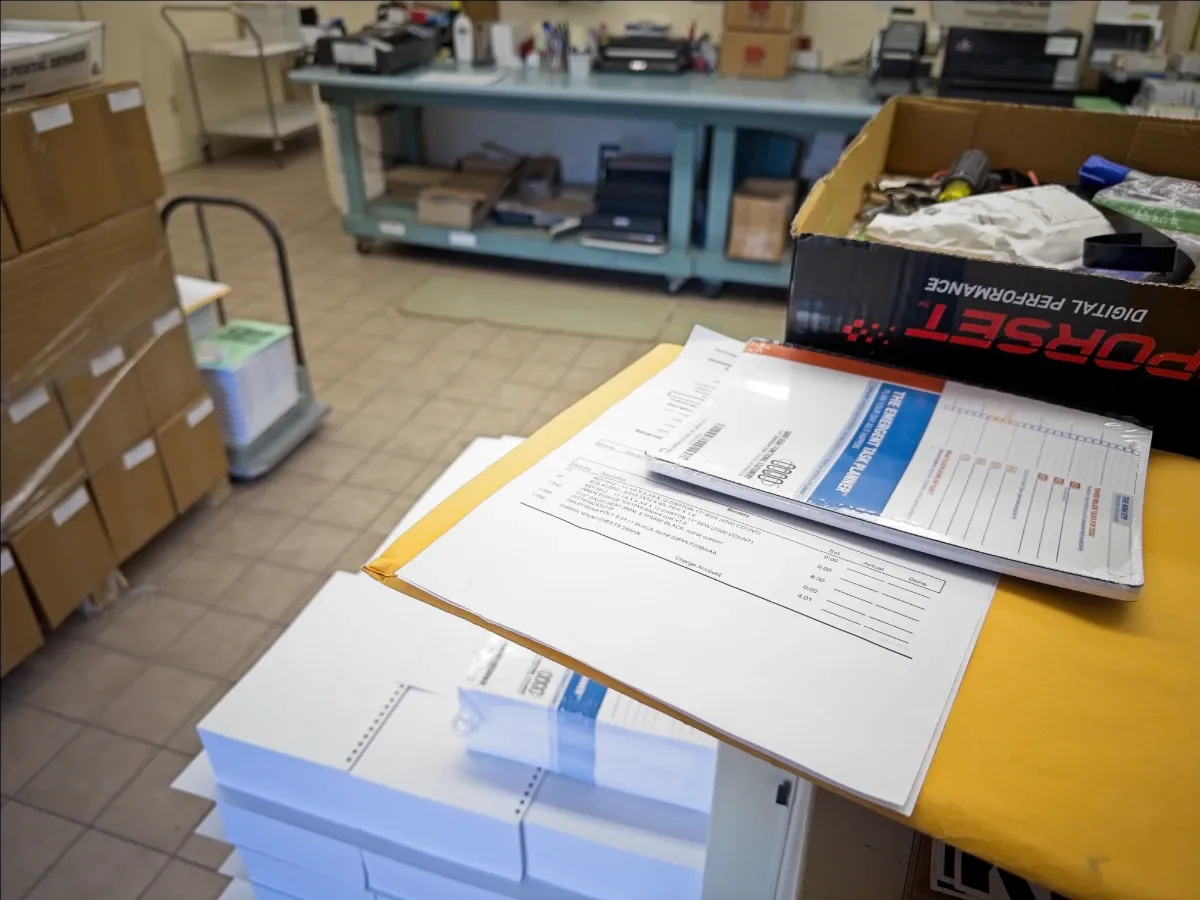

The packaged notebook also includes a process-color insert. Since there are only one of these per package, it’s cost efficient to print these on the digital press. According to the Papergraphics website it’s a Kodak Nexpress ZX3300.

ASIDE: I’m thinking of using the digital press to make short-run projects, since the cost of setup is less than the Heidelberg. What’s kept me from doing this other than other work has been Amazon’s irritating marketplace listing system. Hopefully I’ll get a non-Amazon solution up.

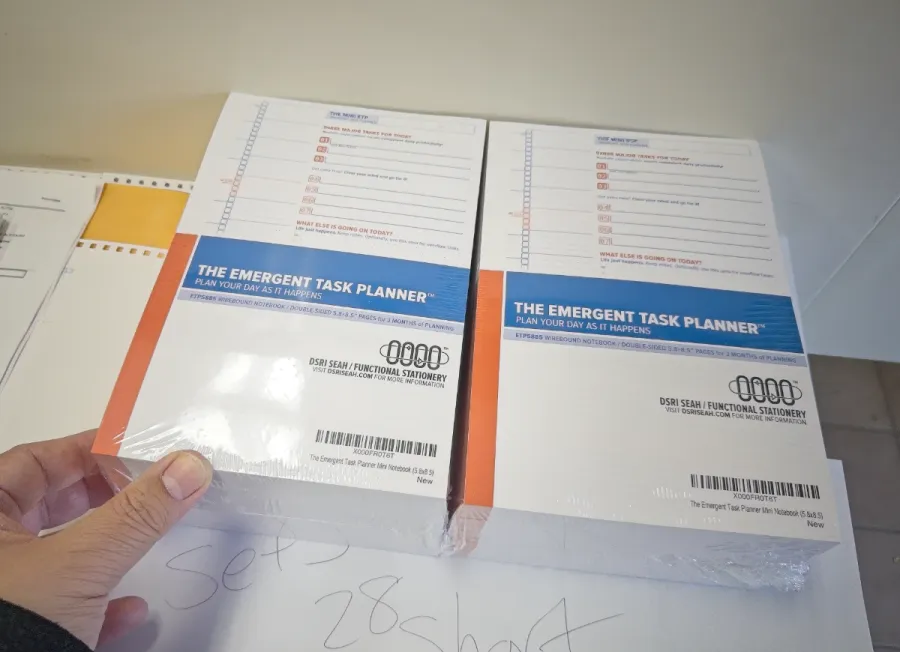

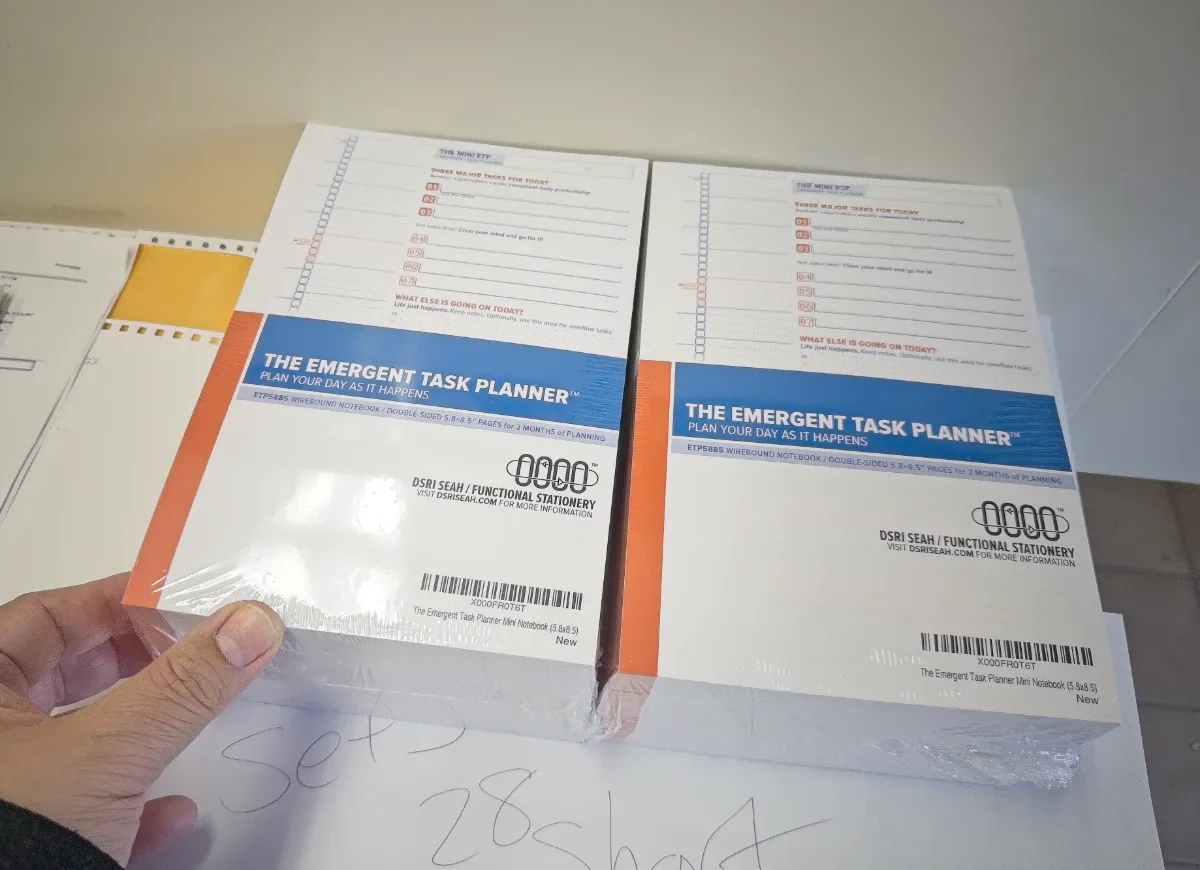

The finished pages are cut and shrinkwrapped for protection until the notebooks are ready to be assembled.

Notebook Assembly

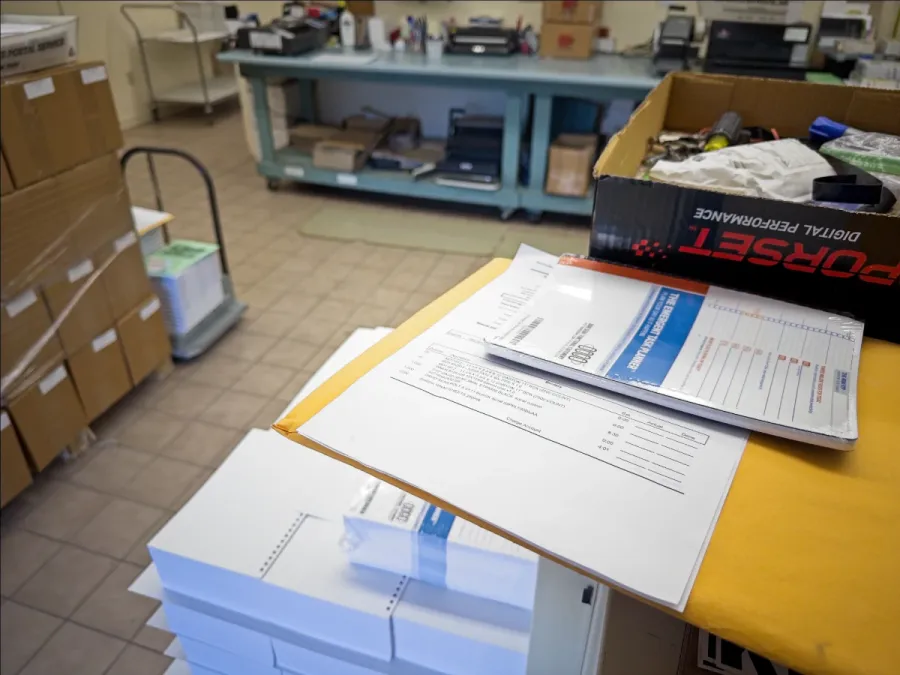

All the components for the ETP Mini Notebook await in this staging area for when they are ready to put everything together. This includes:

- counting the pages into 46-page blocks

- add the front and end pages

- add the front and back vinyl covers

- punch the paper for double-wire spiral binding

- round the corners so the notebook won’t bite you

- add the front insert, shrinkwrap, and pack

This block of paper is what will go inside of the notebook. There’s a machine that automatically counts the pages while punching them, I think.

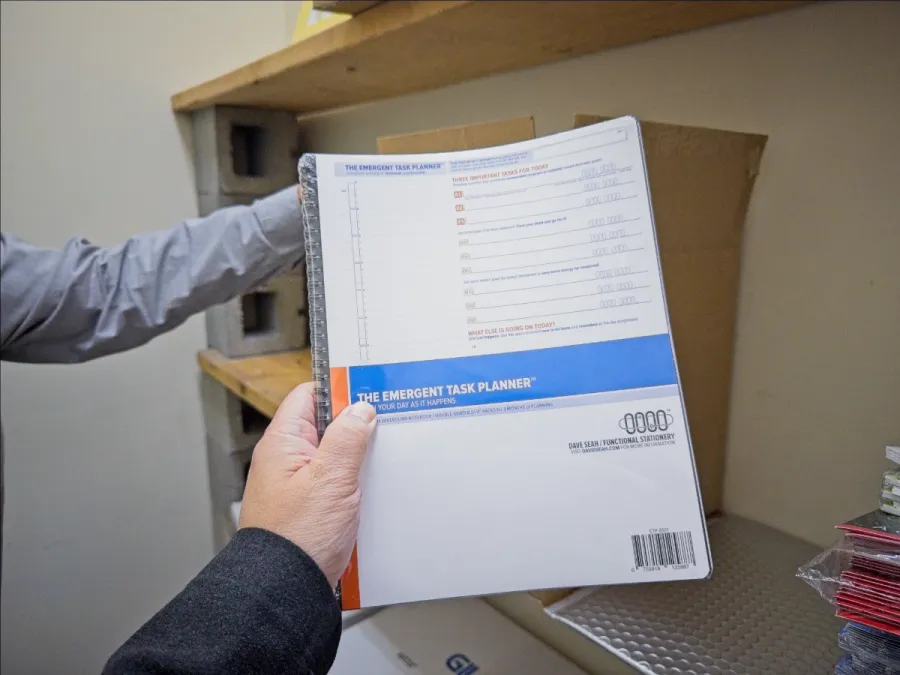

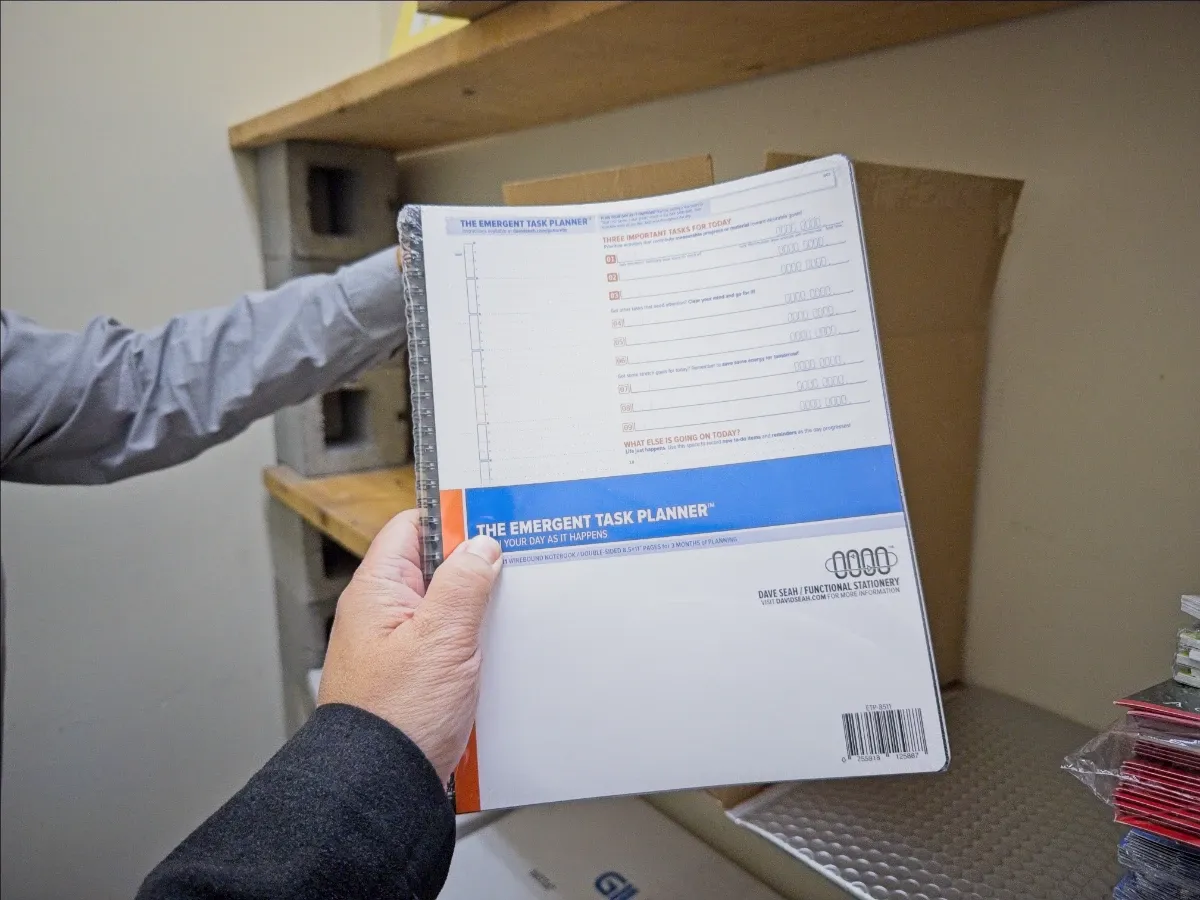

The final result looks like this rare 8811 Full Size ETP Notebook that Frank found in a box in the storage area:

Availability

I told Frank that he could take all the time he needed to get to assembly and packing for fulfillment, since they are super busy right now. Knowing that they are working their assess off doing complicated and meticulous work to make my print job look as great as possible, I’m happy to give them the time.

It’s probably going to be 2-3 more weeks before 250 or so of these make their way to The Emergent Task Planner 3-Month Mini Notebook on Amazon. By the time this run sells-through on Amazon, I’m hoping to have an alternative marketplace working because selling on Amazon now suuuuucks.

2025 Building Challenge Posts

Making an URSYS App Example

Adding Typescript support to Eleventy

Review of Old Design Work

Improving my Eleventy Atom Feeds

Managing a Productivity Crash

Activity Bingo Board: Layout with Affinity Designer

ETP 5885 Notebook Press Run Prep

Activity Bingo Board Revisions

ETP 5885 Notebook Press Tour

A Silly Pass at Logo Design

Unprofessional Business Cards

Word Counting Calendar PDF Quickie Reuse

Word Counting Calendar PDF Now Available!

Word Counting Calendar Preparing to Code

Word Counting Calendar Simple Beginnings

Articulating Friendship

First skip day due to day trip to Concord, etc.

Making a PDF-LIB Reference

Word Counting Calendar Drawing Blocks

Minimum Progress Despite Nausea

Word Counting Calendar Drawing Blocks II

Writing A Mythical Magical Adventure Cat Primer

Word Counting Calendar Drawing Days

Word Counting Calendar Drawing Spaces

A Restorative Visit to the North Shore

Word Counting Calendar: Alpha Release!

ETP 5885 Notebook Production Update!

Personal Cards Revisited

11/21 - Visiting an Old Friend in Beverly, MA

Experimental Collaboration

Short Productive Sprint Day

Thanksgiving Reset Break

ETP 5885 Notebook back on Amazon!

ETP 365 Day Journal Updated for 2026!

Making a Freelance Services Page

BUILD CHALLENGE COMMENTARY

Even though the tour itself took only about 45 minutes door-to-door, I’m only just finishing up with this blog post at 3:30PM. I’ve got to run to an event tonight, so this was what I could manage for today’s Building Challenge.

While I didn’t directly produce a tangible sharepiece myself, I think sharing the behind-the-scenes of product production is still pretty awesome.

BONUS ACHIEVEMENTS

It was great to visit Papergraphics and be reminded of what they can do there. It was even better to connect with Frank again, who has been a stalwart business partner in this project for many years. I was reminded how much I like printers and paper, and as a result I’m feeling pretty excited about doing more of this.

Build 08/30: Activity Bingo Board Revisions

Build 10/30: A Silly Pass at Logo Design

Do you like to chat about the projects you are working on throughout the day? My Discord server is all about that! Come say hi! I can also be reached on Mastodon and Bluesky.